As people become more aware of the environmental impacts of common fabrics such as cotton, they are turning to industrial hemp as a potentially greener alternative. Hemp fabric is a natural material made from the stems of the Cannabis plant species. These days, the fabric is used to make everything from T-shirts to underwear.

The lure of hemp has been two-fold: It is an environmentally friendly fabric and has great benefits to the user. Coming from a natural renewable source, the fabric is biodegradable as well as one of the stronger textile fabrics, which makes its use in clothing ideal. Hemp fabric offers insulating, anti-radiation, and anti-bacterial properties, as well.

How Hemp Fabric Is Made

Hemp fabric is made in a four-step process — planting, harvesting, extraction, and weaving. While seemingly simple, this is a rather involved and labor intensive process. Each step must be optimized for the specific end use.

When planting the seeds for fiber, seeds are sown in close proximity to allow for little branching and taller stems. This allows for more plants, which equals a higher fiber output. However, too many plants in one area can cause the stems to thin as they grow. While some fields aim for higher yields, those in Europe are optimized by planting no more than 182,000 plants per acre — resulting in a better quality fabric.

Harvesting this fiber is just as technical. When producing fiber, the hemp stems are cut during the early stages of blooming when the lower leaves on the female plants begin to yellow. They are then left in rows called windrows and allowed to dry. When they are at 12% moisture content, they are baled and carried to a different location for processing.

The main step in preparing hemp stems for fiber production is retting. This process is similar to that of linen production, and some scientists have looked into the use of linen factories in manufacturing hemp fabric.1 Dew retting is the most common method of extracting the fiber from the stalks. It involves leaving the cut stems in the field to decompose and separate the fibers. The hemp is then crushed to fully remove the fibers, which are then cleaned in preparation for spinning into yarn.

Is Hemp Fabric Sustainable?

Despite its labor-intensive process, hemp is regarded as one of the most sustainable crops on the planet. But the question at hand is whether hemp fabric is just as sustainable.

Advantages

Hemp is naturally disease resistant and can be grown without pesticides, herbicides, and fungicides. Hemp fibers, in particular, have been shown to possess anti-bacterial properties.2 They are also said to be UV protectant, which extends to its use as a fabric. One surprising advantage is the transfer of its antioxidant characteristics. The effectiveness, however, is dependent on the fiber extraction method and subsequent processing methods. Decortication, a dry method of breaking apart and extracting the fibers, yielded the best results.3

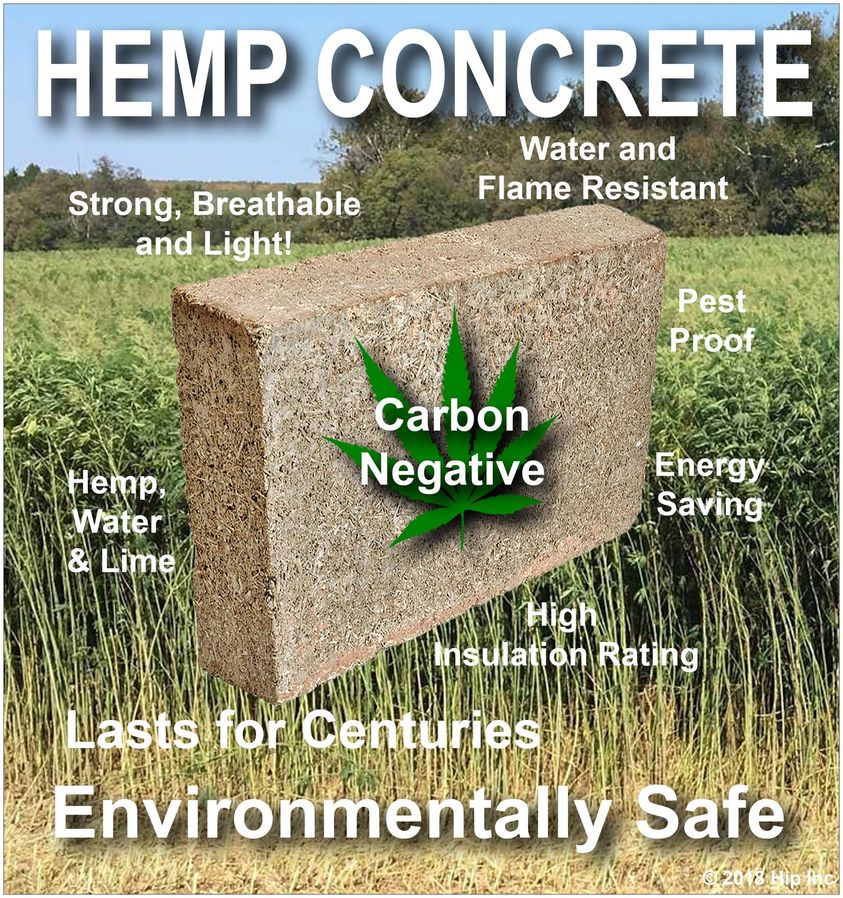

Hemp clothing is also extremely breathable and can keep you warm in cooler temperatures or cooler in hot weather. This insulation property makes it not only useful in clothing but in building materials. And because of the fabric’s strength, a hemp shirt won’t wear out as quickly as others.

Hemp is also environmentally friendly at the end of a product’s life cycle. If a product is 100% hemp or blended with other natural materials, it is most likely completely biodegradable and can be composted.

Disadvantages

While hemp can be processed and woven to be softer than cotton, it is generally seen as a rough fabric. Because of this, it is often combined with other fibers. If these added fibers are synthetic, they lessen the product’s biodegradability. The blending of fibers can also lessen the effect of many of hemp’s benefits.

The fiber of hemp may be extremely sturdy, but the plant itself is not. Like any other crop, hemp is subject to the whims of nature. Properties of the fiber are dependent on the weathering conditions the crop is grown under.

While much of the process as been mechanized, harvesting the crop and extracting the fibers from the hemp plant can be quite labor intensive. Dew retting is the most common method of breaking down the fibers, but it is reliant on favorable weather conditions and can lead to inconsistent fiber quality. Wet retting, however, involves the use of a significant amount of clean water which then has to be treated prior to discarding.

Hemp vs. Cotton

Cotton is currently the most used natural material for clothing. Because of this, cotton and hemp are compared to each other often. Most hemp enthusiasts will tell you that hemp is far more advantageous ecologically. From the stand point of cultivation, this reasoning stands. Hemp needs less water, land, and pesticides to grow and yields three times more metric tons of fiber.4 It has also proven to be economically viable. An added advantage is that it can be grown in many parts of the world.

However, the process of extracting the fibers for hemp expends a lot of CO2 . A comprehensive study on textile materials organized by the Stockholm Environment Institute showed that cotton required less energy to be produced.5 Even though organic cotton is costly, hemp costs even more because of its lack of availability. This is another reason hemp is commonly combined with cotton: It reduces the cost of the fabric. Until hemp is more widely available, this is likely to always be the case.

The Future of Hemp Fabric

Despite the cost of hemp fabric, the possibility of it becoming a more environmentally friendly textile remains. The signing of the 2018 Farm Bill in the United States only strengthens this belief, and the popularity of hemp clothes continues to rise. The future of hemp alone also looks bright, with its usage going beyond clothing textiles. The crop is expected to be worth $14.67 billion by 2026 on the global market.6 From clothing to construction materials to health and wellness products, this Cannabis plant crosses a wide range of industries.

Frequently Asked Questions

- What makes hemp fabric more breathable than other materials?The naturally porous nature of hemp fiber makes the fabric more breathable.

- Is hemp clothing durable?Due to the coarse texture of hemp fibers, hemp fabric, and clothing made with the fabric, is strong and durable.

This article was first published here.

Sources: - Vandepitte, Katrien et al. “Hemp (Cannabis Sativa L.) For High-Value Textile Applications: The Effective Long Fiber Yield And Quality Of Different Hemp Varieties, Processed Using Industrial Flax Equipment.” Industrial Crops And Products, vol. 158, 2020, p. 112969., doi:10.1016/j.indcrop.2020.112969

- Khan, Belas Ahmed et al. “Antibacterial Properties Of Hemp And Other Natural Fibre Plants: A Review.” Bioresources, vol. 9, no. 2, 2014, pp. 3642-3659., doi:10.15376/biores.9.2.3642-3659

- Zimniewska, Malgorzata et al. “Antioxidant Potential Of Hemp And Flax Fibers Depending On Their Chemical Composition.” Molecules, vol. 23, no. 8, 2018, p. 1993., doi:10.3390/molecules23081993

- Duque Schumacher, Ana Gabriela et al. “Industrial Hemp Fiber: A Sustainable And Economical Alternative To Cotton.” Journal Of Cleaner Production, vol. 268, 2020, p. 122180., doi:10.1016/j.jclepro.2020.122180

- Cherrett, Nia et al. Ecological Footprint And Water Analysis Of Cotton, Hemp And Polyester. Stockholm Environmental Institute, 2005.

- “Industrial Hemp Market By Product (Seeds, Fiber, Shivs), Nature, Application Region Global Industry Analysis, Market Product, Share, Growth, Trends, And Forecast 2019 To 2026.” Fior Markets, 2019.