Hemp materials and conventional building materials differ in several ways, including their environmental impact, cost, durability, and versatility. Here’s a comparison of hemp materials to conventional building materials:

Environmental Impact:

Hemp Materials: ![]()

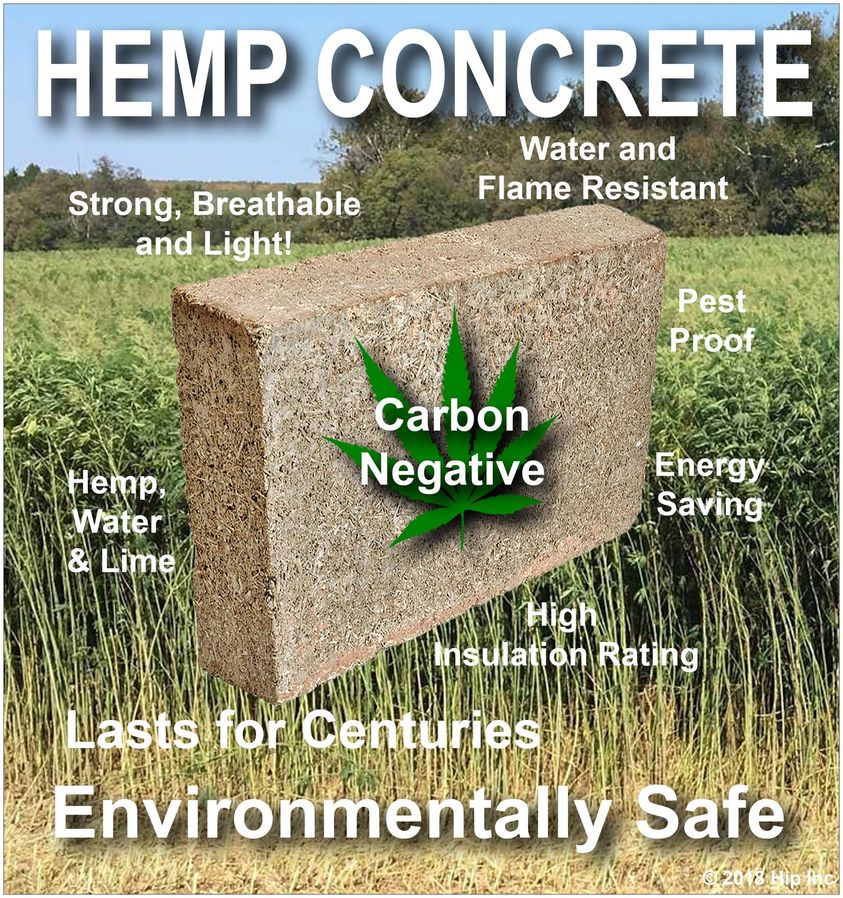

Hemp is a highly sustainable crop that requires minimal water, pesticides, and herbicides. It absorbs carbon dioxide during its growth, making it a carbon-negative material. Hemp-based materials are biodegradable and can be recycled.

Conventional Materials: ![]()

Many conventional building materials, such as concrete and steel, have a significant environmental footprint due to resource-intensive extraction, energy consumption, and greenhouse gas emissions. These materials often contribute to land degradation and pollution.

Renewability:

Hemp Materials: ![]()

Hemp can be harvested annually, making it a renewable resource. Its quick growth cycle means a constant supply for construction.

Conventional Materials: ![]()

Some conventional materials, like timber, can be renewable when sourced sustainably. However, non-renewable materials like concrete and steel are finite resources.

Insulation:

Hemp Materials: ![]()

Hemp can be used to create insulation materials that have excellent thermal and acoustic properties. Hempcrete, a mixture of hemp fibers, lime, and water, is a popular choice for insulating walls and roofs.

Conventional Materials: ![]()

Conventional materials, such as fiberglass and foam board, are commonly used for insulation. They may have good insulating properties but can be less eco-friendly.

Strength:

Hemp Materials: ![]()

Hemp fibers can provide reasonable tensile strength. However, they are not as strong as materials like steel or concrete.

Conventional Materials: ![]()

Conventional materials like steel and concrete offer high structural strength and are commonly used in load-bearing components.

Weight:

Hemp Materials: ![]()

Hemp-based materials are typically lighter than many conventional materials, which can be advantageous for certain construction applications.

Conventional Materials: ![]()

Conventional materials vary in weight, with some being very heavy, like concrete and steel.

Cost:

Hemp Materials: ![]()

Hemp materials may have a higher initial cost due to limited availability and processing infrastructure. However, they can be cost-effective in the long run due to energy savings and reduced maintenance.

Conventional Materials: ![]()

The cost of conventional materials can vary widely but is often influenced by market demand, availability, and location.

Regulations:

Hemp Materials: ![]()

Regulations related to the use of hemp-based construction materials vary by region and may pose challenges in some areas due to the association with cannabis.

Conventional Materials: ![]()

Conventional materials are well-established and regulated in most regions, making them easier to source and use.

Versatility:

Hemp Materials: ![]()

Hemp can be used for a variety of building components, including insulation, structural elements, and finishes. It offers design flexibility.

Conventional Materials: ![]()

Conventional materials have a long history of use and can be adapted to various construction needs.

In summary, hemp materials offer several eco-friendly advantages, particularly in terms of sustainability and insulation. However, they may not be suitable for all construction applications due to differences in strength and regulation. The choice between hemp and conventional materials depends on project goals, local availability, and regulatory considerations.

Learn to build with hemp with the top builders in the US #hempbuilding space.

For more details: https://www.hempbuildmag.com/hemp-build-school

#HempBuildSchool#HempBuildSchoolMastermind#Hemp#HempBuilding#SustainableConstruction#GreenBuilding#EcoFriendlyHomes#Hempcrete#SustainableMaterials#HempFiber#RenewableResource#HempInsulation#CarbonNegative#NaturalBuilding#ZeroWaste

#BuildingWithHemp#HealthyHomes#HempRenewable

#LowCarbonFootprint#GreenArchitecture#SustainableDesign#NaturalMaterials#GreenLiving#EnvironmentalConstruction#SustainableLiving#HempSolutions

#GreenBuilders#HempConstruction

__________

This post was taken over from Hemp Build School Mastermind